Sorry, your cart is empty :(

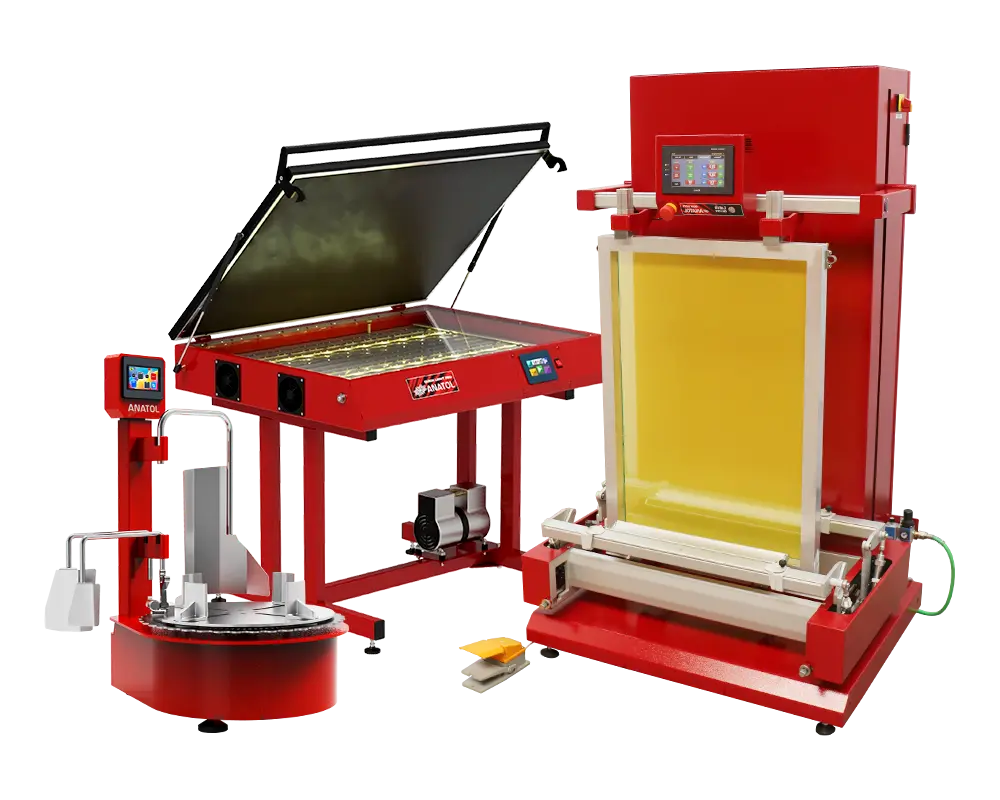

The Quik-Kote Mini from Anatol is an innovative and compact automatic emulsion coating machine. It delivers exceptional precision, efficiency, and high-quality prints, unlocking the full potential of your screen printing process. Replace manual coating with a smooth, efficient pre-press process that saves time and enhances your print quality.

The Quik-Kote Mini is a powerful solution designed to accelerate screen preparation and ensure consistent, high-quality prints. This affordable, high-performance solution is ideal for small to medium-sized print shops. It eliminates manual coating errors, saves valuable time, and consistently delivers impressive results. Whether you’re scaling up or refining your craft, the Quik-Kote Mini empowers you to produce with confidence.

Discover how the Quik-Kote Mini can streamline and elevate your workflow. Pair it with the optional Quik-Kote coating scoop accessory for even more flexibility and efficiency.

| Dimensions | 67.3’’ x 39.4’’ x 28’’ (171cm x 100cm x 71.1cm) |

| Weight | 460lb (210kg) |

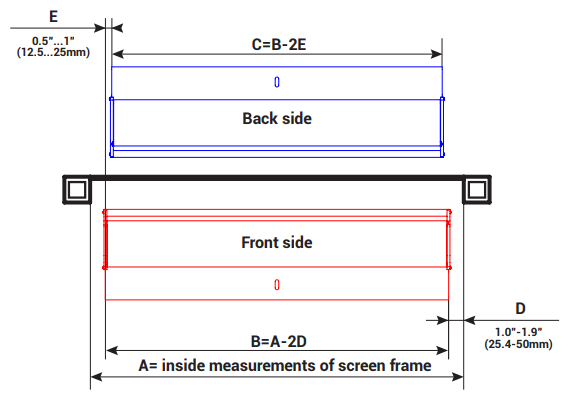

| Compatible Screen Size | 15.5’’ x 43’’ (39.37cm x 109.22cm) |

| Compatible Screen Frame Thickness | 0.75’’ x 0.75’’ up to 0.8’’ x 2’’ (2cm x 2cm up to 2.2cm x 5cm) |

| Air Requirements | 0.56 CFM (16 l/min) @60PSI |

| Air Pressure | 58 PSI (4 bar) |

| ELECTRICAL REQUIREMENTS | 1ph, 208-240V, 50/60Hz, 4A Max Power: 850W |

pre-press equipment

Your message was successfully sent!