Sorry, your cart is empty :(

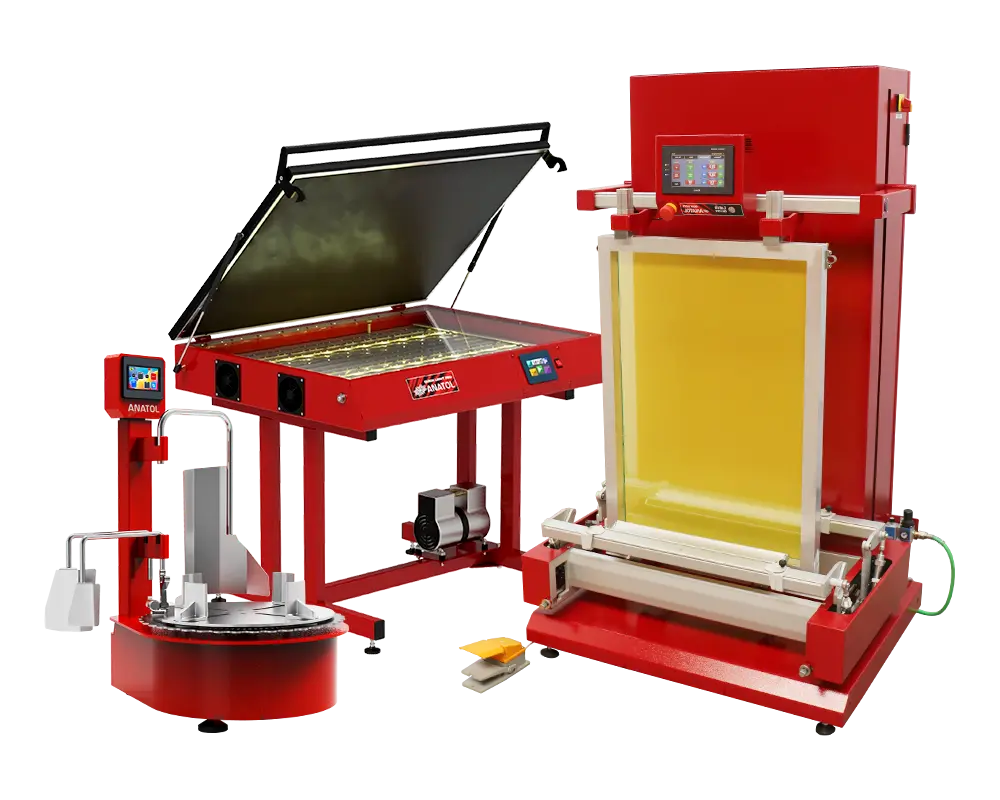

– Independent control of the right and left mixing tables (mixing speed, time and direction)

– Set of six easy-to-clean, stainless steel mixing blades included: quart (x2), gallon (x2), 6-gallon (x2)

– Accepts the full range of U.S and international container sizes including

1 quart, 1 gallon, 6 gallons and all sizes in between (2 to 22.7 liters).

We have also available other models of the Formulator ink Mixer: Ink Mixer Big and Ink Mixer Mini.

The Anatol Formulator Double Ink Mixer is a powerful and versatile tool designed for professional print shops. Use it to enhance the quality and efficiency of your screen printing.

The dual-container ink mixer delivers accurate and efficient mixing. It easily blends plastisol, water-based inks, pigments, glitters, fluorescents, reducers, and other additives. It ensures a consistent, high-quality mix every time.

The Anatol Formulator Double Ink Mixer is a must-have for screen printing shops seeking precision, flexibility, and efficiency. Thanks to its adjustable speed control and dual-container design, the Formulator ensures precise mixing. Its splash-free technology helps print shops deliver superior print quality with ease. Backed by Anatol Equipment Manufacturing Co.’s limited warranty, this mixer guarantees reliable performance and peace of mind.

| MODEL | WEIGHT | INK VOLUME | OUTER DIMENSIONS WXDXH | ELECTRICAL REQUIREMENTS |

|---|---|---|---|---|

| DOUBLE MIXER | 207lbs (94 kg) |

up 1/4G (0.95L) x2 to 6G (22.7L) x2 |

38.2” x 26.1” x 33.4” 970mm x 663mm x 847.5 mm |

1 Phase, 110V, 15A 1 Phase 208-240V, 13A |

pre-press equipment

Your message was successfully sent!