Sorry, your cart is empty :(

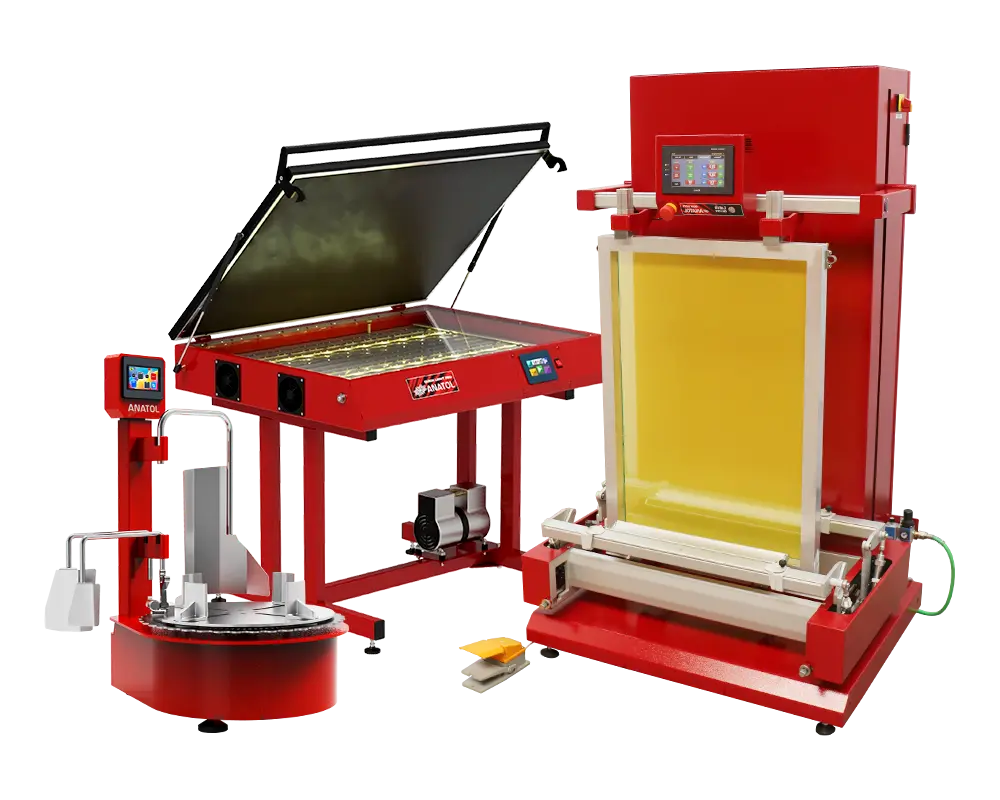

Accepts containers from one quart up to one gallon.

– Two easy-to-clean, stainless steel mixing blades (quart, gallon) included

– Accepts container sizes from 1 quart up to 1 gallon and all sizes in between

(1 liter to 3.75 liters).

We have also available other models of the Formulator ink Mixer: Ink Mixer Big and Ink Mixer Double.

Improve your screen printing with the Anatol Formulator Mini, a compact but powerful industrial mixer that simplifies ink preparation. This machine automatically mixes plastisol and water-based inks, delivering consistent, high-quality results without manual effort. Ideal for small to medium print shops, the Formulator Mini works with containers from one quart to one gallon. Versatile for mixing pigments, specialty inks, reducers, and modifiers to achieve perfect printing consistency.

Anatol designed the Formulator Mini for reliability and user safety. It meets strict safety standards outlined in its comprehensive manual. A variable frequency drive and gear motor ensure smooth, consistent operation.

The touchscreen panel makes setup simple, offering programmable controls for speed, time, and rotation direction. Whether you’re preparing specialty inks or maintaining consistency, the mixer boosts productivity and reduces manual effort. A must-have tool for professional screen printers.

The Formulator Mini is easy to set up and arrives securely packaged in a wooden box. After unpacking, assemble the column to the body using two M12 bolts. Attach the appropriate mixing blade and secure the ink container on the turntable using the adjustable clamp.

For optimal performance, place the mixer on a flat, dry, dust-free surface. The intuitive touchscreen lets operators choose between Manual, Automatic, and Custom modes. Each mode offers detailed settings for speed, time, and direction, providing precise control over the mixing process.

Anatol protects your investment in the Formulator Mini with a limited warranty. It includes repair or replacement of parts and labor for defects in materials or workmanship. Please note that the warranty does not cover expendable parts, misuse, or unauthorized modifications. Make your ink preparation easier with the Anatol Formulator Mini Screen Printing Ink Mixer. Compact, efficient, and designed for professional results.

| MODEL | WEIGHT | INK VOLUME | OUTER DIMENSIONS WXDXH | ELECTRICAL REQUIREMENTS |

|---|---|---|---|---|

| MINI MIXER | 55lb (25 kg) |

up 1/4G (0.95L) to 1G (3.8L) |

16.5” x 22.6” x 25.8” 418mm x 575mm x 655mm |

1 Phase, 110V, 9A 1 Phase 208-240V, 6.5A |

pre-press equipment

Your message was successfully sent!