Sorry, your cart is empty :(

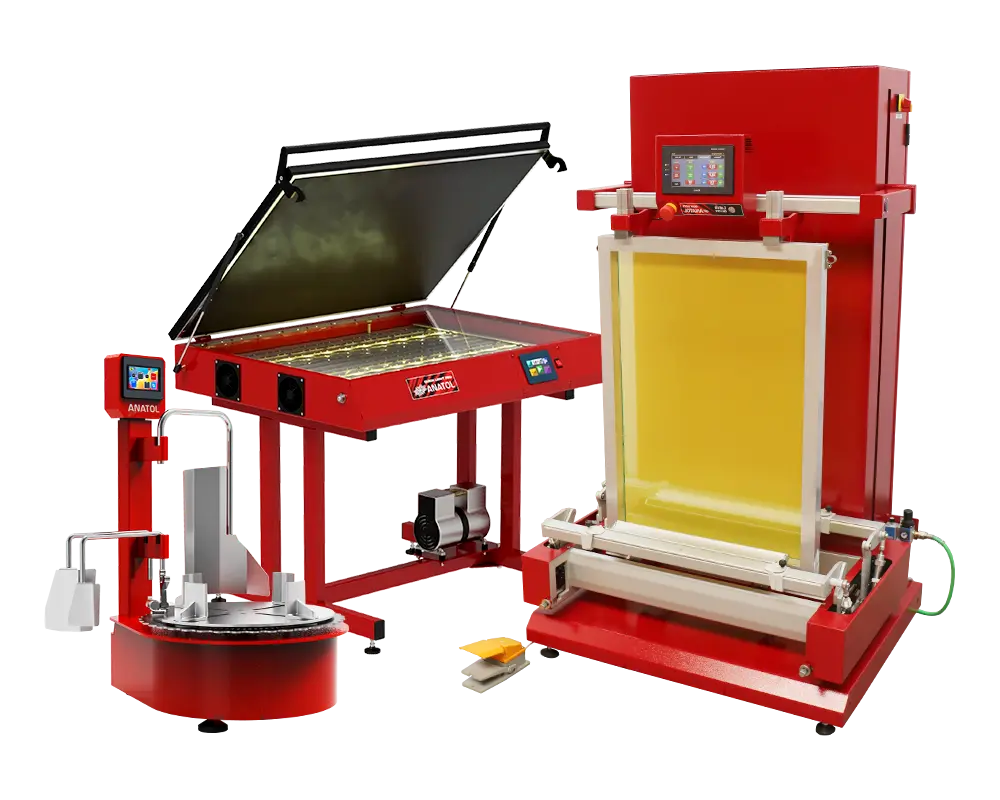

Anatol’s Pilot Flash is a powerful quartz flash dryer designed for screen printing. It provides fast and reliable curing across a wide range of materials.

This innovative flash curing system features ultra-fast medium-wave quartz lamps and a compact, mobile design. It delivers full substrate coverage without the need for a large or stationary flash dryer.

The Pilot Flash is ideal for high-volume production and works seamlessly with Anatol’s automatic screen printing presses.

This quartz flash cure unit enhances your screen printing workflow with precision and speed. Its unique features make it an ideal flash cure unit for screen printing operations of any scale:

The Anatol Pilot quartz flash cure unit for screen printing stands out for its efficiency and flexibility. Here’s why it’s a must-have for your print shop:

The Pilot flash cure unit for screen printing is available in multiple configurations to suit your needs:

The Pilot quartz flash cure unit is ideal for a variety of screen printing applications, including:

Whether you run a small print shop or a large production facility, this curing system provides consistent results.

What makes the Pilot Flash different from other curing units?

The Pilot Flash is a quartz flash cure unit for screen printing. It combines mobility, fast-curing quartz lamps, and seamless integration with Anatol presses to deliver unmatched efficiency and flexibility.

Can the Pilot Flash handle/large substrates?

Yes, with widths up to 40″, the quartz curing unit provides full coverage for even the largest garments and substrates.

How straightforward is the installation process for the Pilot Flash?

Absolutely. The Pilot flash cure unit attaches easily to the print carriage. It works smoothly with Anatol’s touchscreen controls for a quick and hassle-free setup.

| Model # | Width | Number of Lamps | Electrical Requirements |

|---|---|---|---|

| PILOT-16 | 16″ 41cm |

4 | 1 Ph, 208-240V, 50/60 Hz, 4kW, 19A 3 Ph, 208-240V, 50/60 Hz, 4kW, 11A |

| PILOT-20 | 20″ 51cm |

5 | 1 Ph, 208-240V, 50/60 Hz, 6kW, 31A 3 Ph, 208-240V, 50/60 Hz, 6kW, 18A |

| PILOT-30 | 30″ 71cm |

12 | 1 Ph, 208-240V, 50/60 Hz, 12kW, 58A 3 Ph, 208-240V, 50/60 Hz, 12kW, 33A |

| PILOT-40 | 40″ 102cm |

12 | 1 Ph, 208-240V, 50/60 Hz, 15kW, 72A 3 Ph, 208-240V, 50/60 Hz, 15kW, 42A |

pre-press equipment

Your message was successfully sent!