Sorry, your cart is empty :(

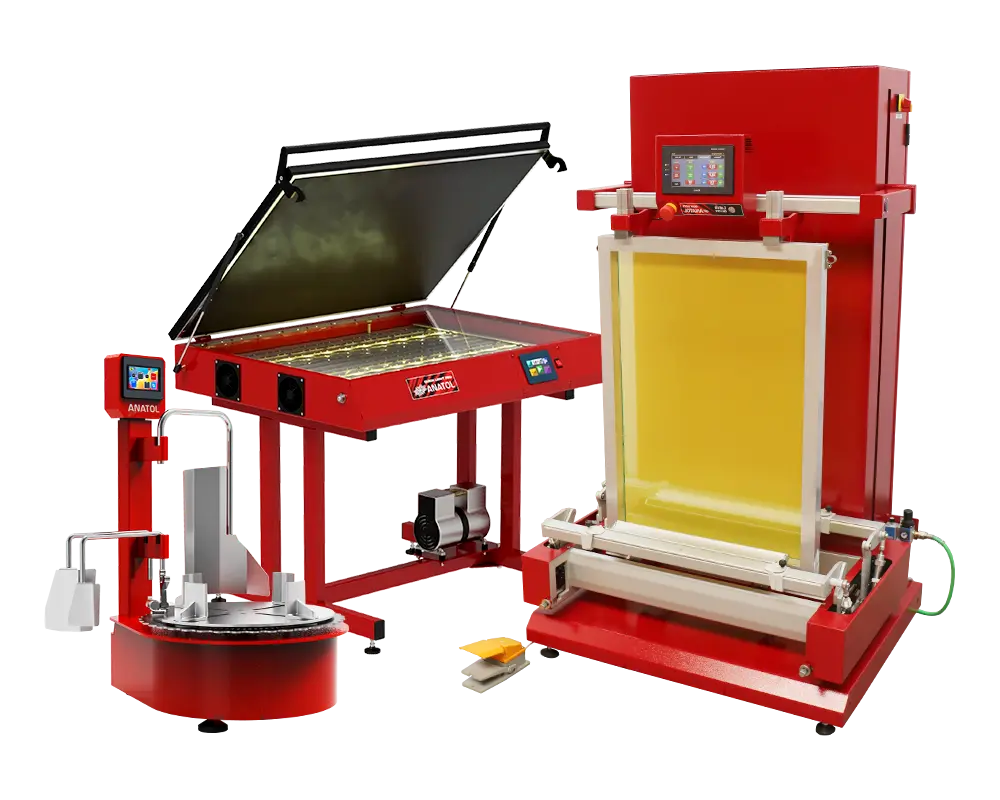

To use the Comet Light flash cure unit with a manual press, add the optional Timer Box.

The speed and efficiency of quartz flash curing in our most affordable package.

Anatol’s Comet Light flash cure unit was designed to boost your shop’s efficiency compared to infrared flashes, while being accessible to shops on a budget. Just set your curing time and the optical sensor on the flash unit will automatically detect when a shirt is underneath, activating and deactivating the lamps accordingly. The Comet Light is available in three different curing areas – 16″ x 18″, 20″ x 24”, and 20″ x 28″ – and is compatible with Anatol automatic presses, as well as manual presses with the addition of the optional Timer Box (see above).

The Smart Flash Polymerization Unit is an efficient system for polymerizing your products. The Smart Flash Curing Unit is indispensable for screen printing, silk screening and t-shirt printing. Mobility and energy savings in production have always been considered good indicators. That is why the Anatol quartz curing unit is in high demand in the screen printing market.

| COMET LIGHT SIZE |

NUMBER OF LAMPS |

NUMBER OF CURING ZONES | HEAT FLUX DENSITY | ELECTRICAL REQUIREMENTS* |

|---|---|---|---|---|

| 16”x 18” 46.0х96.9cm (52.3×96.9cm)** |

9 Lamps | 2 zones (Zone I -6 lamps, Zone II – 3 lamps) |

4.47 W/cm2 (28.87 W/in2) |

1 Ph, 208-240V, 50/60 Hz, 9kW, 43.3A 3 Ph, 208V, 28.9A |

| 20”x 24” 58.0×110.4cm (64.3×110.4cm)** |

10 Lamps | 2 zones (Zone I -6 lamps, Zone II – 4 lamps) |

3.8 W/cm2 (24.53 W/in2) |

1 Ph, 208-240V, 50/60 Hz, 12kW, 60.1A 3 Ph, 208V, 42A |

| 20”x 28” 58.0×120.0cm (64.3×120.0cm)** |

15 Lamps | 3 zones (Zone I -5 lamps, Zone II – 5 lamps, Zone III – 5 lamps) |

4.9 W/cm2 (31.61 W/in2) |

1 Ph, 208-240V, 50/60 Hz, 18.75kW, 90A 3 Ph, 208V, 60A |

| * The maximum power consumption is calculated for all lamps operating at maximum power ** The dimensions in parentheses mean are the dimensions with the electrical box included |

||||

pre-press equipment

Your message was successfully sent!