Sorry, your cart is empty :(

In screen printing, few factors influence print quality and production speed as much as screen tension. High, consistent mesh tension ensures fast snap-off, clean ink release, sharp details, and smooth flooding. Low tension, on the other hand, slows production, causes smearing, uneven ink deposits, and leads to rapid stencil and mesh wear.

Optimize your screen printing darkroom with Anatol’s VOLT press and automatic coating machines. Learn screen reclamation best practices, determine the right number of screens, and boost efficiency. Streamline your setup to enhance print quality, reduce costs, and handle high-volume jobs effectively. Revolutionize your shop today!

VOLT by Anatol — Supercharge Your Screen Printing, Save Time and Money.

Take back your time, cut your costs, and leave pneumatic problems behind for good.

With Section 179 of the IRS tax code, you can deduct the total cost of qualified equipment you buy in 2025, up to $3,130,000 in total purchases. You can also take advantage of 40% bonus depreciation on both new and used equipment purchased in 2025. Act now before the year ends.

Flashing is a critical step in the screen printing process, especially when working with multi-color designs or specialty inks. It refers to the process of briefly curing the ink between print strokes using a flash dryer.

Screen printing, from ancient Chinese stencils to modern automated systems, blends tradition with innovation, creating vibrant, durable designs on various surfaces

High density printing is a unique screen printing technique that creates bold, raised, and vibrant designs with a premium look. By applying thick layers of ink, it delivers long-lasting colors, tactile appeal, and eye-catching graphics. Discover how this method helps brands and designers produce unforgettable apparel with maximum visual impact.

Discover how to boost your screen printing speed without sacrificing quality. From choosing the right equipment and inks to streamlining setup, curing, and team training, these practical tips help you achieve faster turnaround times while keeping prints sharp and professional.

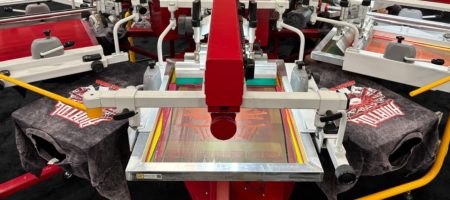

Anatol Automatic Screen Printing Presses: Save time, Energy, and Money For most screen printing shop owners, producing quality prints is the easy part. The real challenge is managing day-to-day operations, meeting business goals, and ensuring your company continues to grow. If your business feels stagnant, it might be time to take a hard look at […]

Conveyor dryers are essential for high-quality screen printing, but common mistakes can hurt results. This article covers four key issues—wrong temperature, incorrect belt speed, poor maintenance, and overloading—and offers practical solutions. Learn how Anatol’s conveyor dryers help ensure consistent curing and improved efficiency.

Keep your screen printing machine in top shape with our maintenance guide. Learn daily, weekly, and monthly tasks to ensure high-quality prints and avoid downtime. Discover when to call Anatol’s professionals for expert repairs and maximize your equipment’s lifespan.

Pricing is the backbone of a successful screen printing business. This guide helps you calculate true costs, set minimum orders, apply volume discounts, and build a sustainable, profitable pricing strategy.

Your message was successfully sent!